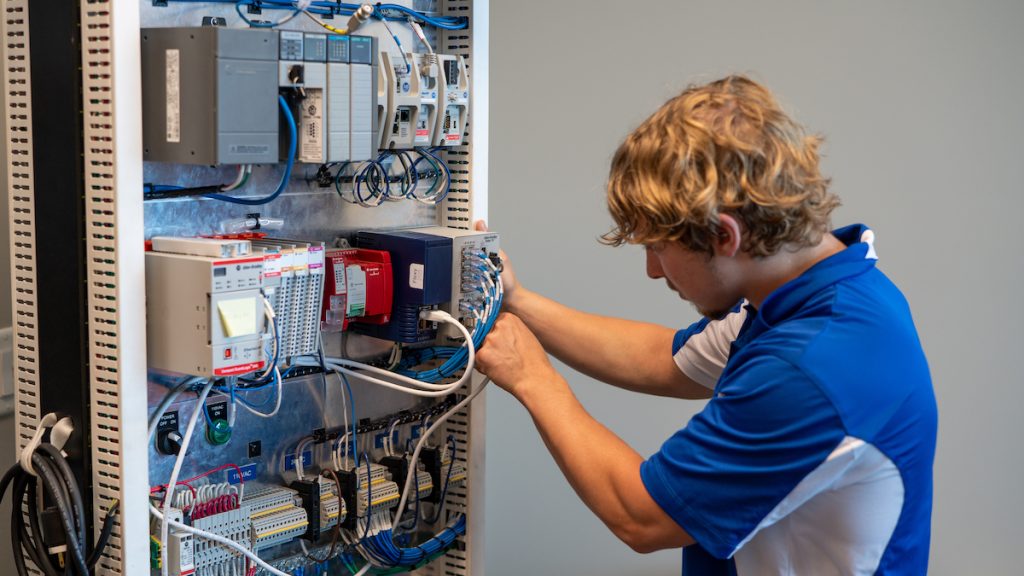

Gansevoort Systems Integrator RASP Has Electronics Support Under Control

When industrial controls and automation company RASP Inc. added a 6,000-square-foot facility to its complex over the summer, its Gansevoort footprint swelled to over 30,000 square feet.

That’s not bad, considering that the company owner started the enterprise nearly three decades earlier on the landing just outside his front door as the only employee.

“It was me from day one,” recalled owner and chief executive officer Ron Richards of the business — then called Protech — he created in 1995. “I was the designer, the programmer, and I built the panels. I was building control panels on my porch at my house.”

In the succeeding 28 years, the enterprise has changed its name (to RASP), moved from its original location (in South Glens Falls), exponentially increased its staff (to the current total of 35 employees), and, now, augmented its building complex.

The new facility “is a combination manufacturing site and offices,” said Richards, who was born and raised in Corinth. The Saratoga County site – originally 22,000 square feet, supplemented four years ago by a 2,500-square-foot facility — simply was not sufficient to keep up with the demand for the company’s services. “We ran out of office space,” Richards said.

Richards, 56, describes his company as a kind of jack-of-all-trades in the electronics industry.

“We’re what’s called a systems integrator, which is just a fancy [term] for ‘we do a lot,’” said Richards with a laugh in a recent telephone interview. “We’re an electrical engineering firm, we’re also programmers for industrial use, we’re also a manufacturer, and we’re also a service company.”

The majority of the staff is composed of panel builders, though RASP currently employs 10 engineer-programmers who “design the control systems that we may or may not build,” Richards said.

On its website, the company lists programming topics such as HMI (human-machine interface) proficiency. For HMIs, commonly known as touch screens, RASP can program, enhance, or customize graphics. One of the topics listed under the RASP website’s “engineering” section is “motion and servo controls,” which Richards said falls under the category of automation.

“It could be a simple motion like a conveyer, or it can be a complicated machine that’s doing a lot of operations,” Richards said. It’s typical for one of RASP’s clients to design a machine, then approach RASP with a fairly direct request: ‘We need this thing to work.’ As Richards explains, “We build the controls, not the machine itself.”

RASP does not make a standalone product of its own. But it does just about everything else.

“We consider ourselves a manufacturer’s extension for other companies,” Richards said. “They come to us. If their machine needs a new control panel, we [can] design it, build it, and program it. It can be a chemical company or a manufacturer in water treatment, medical, power, machine builders — we get to see all kinds of different companies.”

Growing up, Richards attended Corinth High School and studied electronics at BOCES in Saratoga. There, he volunteered for a summer job at Raloid Tool Co. in Mechanicville, where he learned how to make electrical control panels

“That’s how I got introduced to industrial controls,” he said.

Later, after studying electronics at Fulton-Montgomery Community College and going back to work at Raloid (as well as serving a four-year stint in the U.S. Air Force), Richards struck out on his own – with RASP the result.

When the business was incorporated in 1995, Richards and his two original partners — whom he declined to name — used the first letter of their last names plus the “P” in the word “products” to come up with RASP. His current business partner, Michael Close, joined the company in 1997.

Though RASP counts behemoths such as Rockwell international, General Electric, and Emerson Electric among its clients, most come from within a 50-mile radius of its Gansevoort complex. “But because we’re building for other companies, the products can go anywhere in the world,” Richards said. “I have an employee in Canada (and) we’ve done work in New Jersey, we’ve done work (for firms) in Chicago, California, Texas.”

Because of the COVID-19 pandemic and other economic uncertainties, many companies have struggled to stay in business over the past few years. Through nearly three decades, however, RASP has thus far weathered every financial storm.

“We’re in a good position,” Richards said, humbly. “When the economy is doing well, companies are spending money. When the economy is not doing so hot, many companies may downsize, and if they’re downsizing, say, in their maintenance department, then they call on us. Or maybe they are manufacturers themselves, and they can’t support as many engineers, they can call on us on an as-needed basis. So we tend to stay strong in both good and bad economies.”

According to Richards, his primary goal is “keeping the people I have. It’s just a great team. Everyone here – they are team players. They take pride in their work. They do whatever they have to do when asked,” although, he adds, “I don’t have to ask too often.”

While he is happy with his company’s niche in the electronics industry, Richards is not complacent.

“A lot of what we build is what we call one-offs, or low volume. We design and build [a product], and it goes on a machine, or it goes to a customer, and we never build that one again. In the new facility, I’m hoping to build more repeat business. We’re trying to get the word out that we’re looking to handle larger volumes [for a company that needs] to build dozens, or hundreds, or even thousands of something.”

When it comes to electronics support, RASP, it would seem, has it all under control.

For more information, go to rasp-controls.com, email info@rasp-controls.com or call 518-747-8020.